In today’s competitive manufacturing and construction landscape, production efficiency is no longer just a performance metric—it directly impacts profitability, delivery timelines, and product quality. Industries across the UAE and GCC are rapidly adopting advanced fabrication technologies to stay ahead, and laser welding machines have emerged as a game-changing solution.

From precision fabrication and automotive components to structural steel and industrial manufacturing, laser welding offers unmatched speed, accuracy, and consistency. As a trusted laser welding machine supplier, Global Fasteners supports manufacturers and contractors with advanced laser welding solutions designed to transform production efficiency.

This article explores how laser welding machines improve productivity, supported by supplier insights and real-world industry case applications.

What Is Laser Welding and Why Is It Revolutionary?

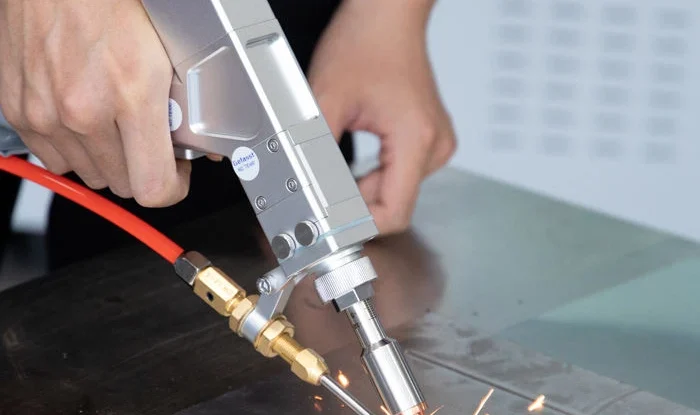

Laser welding is a process that uses a highly focused laser beam to join metals with extreme precision. Unlike conventional welding methods, laser welding concentrates heat in a small area, creating strong, clean welds with minimal distortion.

Key Advantages of Laser Welding:

✔ High welding speed

✔ Minimal heat-affected zone

✔ Superior weld quality

✔ Low post-weld finishing

✔ Automation compatibility

✔ Cleaner and more precise joints

These advantages directly translate into higher productivity and lower operational costs.

How Laser Welding Machines Improve Production Efficiency

1️⃣ Faster Welding Speeds = Higher Throughput

Laser welding machines can perform welds several times faster than traditional MIG or TIG welding.

Impact on production:

-

Reduced cycle times

-

Increased output per shift

-

Faster project completion

For manufacturers handling high-volume parts or repetitive processes, this speed advantage is critical.

2️⃣ Reduced Rework and Material Waste

Traditional welding can lead to:

-

Excess spatter

-

Distortion

-

Inconsistent weld quality

Laser welding delivers:

✔ Clean weld seams

✔ Consistent penetration

✔ Minimal spatter

This means less rework, fewer rejected parts, and reduced material waste, improving cost control.

3️⃣ Precision Welding for Thin & Complex Materials

Laser welding excels in:

-

Thin sheet metal

-

Stainless steel

-

Aluminum

-

Carbon steel

-

Precision components

Its accuracy allows manufacturers to work on complex geometries without damaging surrounding material—expanding production capabilities.

4️⃣ Low Heat Input Improves Structural Integrity

Because laser welding applies focused energy:

-

Base material properties remain intact

-

Warping and deformation are minimized

-

Structural strength is maintained

This is especially important in industrial fasteners, steel structures, and engineered components, where weld quality is directly tied to safety.

5️⃣ Automation & Industry 4.0 Compatibility

Modern laser welding machines integrate easily with:

-

Robotic arms

-

CNC systems

-

Automated production lines

This enables:

✔ Continuous operation

✔ Reduced labor dependency

✔ Improved consistency

✔ Data-driven quality control

For UAE manufacturers adopting Industry 4.0, laser welding is a natural upgrade.

Supplier Insights: Why Industries Are Switching to Laser Welding

As an experienced laser welding machine supplier, Global Fasteners has observed clear trends across UAE and GCC industries.

✅ Shift Toward Precision Manufacturing

Clients demand higher quality finishes with lower tolerances, making laser welding the preferred choice.

✅ Rising Skilled-Labor Costs

Laser welding reduces reliance on manual welding expertise, cutting long-term labor costs.

✅ Focus on Faster Project Turnaround

Contractors and manufacturers need equipment that keeps pace with accelerated construction and manufacturing schedules.

Case Studies: Laser Welding in Real-World Applications

Case Study 1: Structural Steel Fabrication

Challenge:

A fabrication company faced delays due to slow welding speeds and frequent rework on steel assemblies.

Solution:

Adoption of fiber laser welding machines supplied through a trusted vendor.

Results:

-

40% reduction in welding time

-

Improved weld consistency

-

Significant reduction in post-weld grinding

-

Faster project delivery

Case Study 2: Industrial Equipment Manufacturing

Challenge:

High rejection rates caused by heat distortion on thin metal components.

Solution:

Precision laser welding replaced conventional TIG welding.

Results:

-

Near-zero distortion

-

Enhanced product aesthetics

-

Lower scrap rates

-

Improved customer satisfaction

Case Study 3: Fastener & Component Production

Challenge:

Manual welding limited speed and repeatability for specialized industrial components.

Solution:

Automated laser welding integrated into production line.

Results:

-

Higher production output

-

Consistent weld quality

-

Reduced operational costs

-

Scalability for larger orders

Industries Benefiting from Laser Welding Machines

Laser welding machines are now standard across:

🏭 Industrial manufacturing

🏗 Steel structure fabrication

⚙ Fastener and component production

🚗 Automotive and transport industries

🛢 Oil & gas equipment manufacturing

🏢 Construction & infrastructure projects

Their versatility makes them ideal for both small workshops and large-scale factories.

Choosing the Right Laser Welding Machine Supplier

Not all machines—or suppliers—are equal. When selecting a laser welding machine supplier, look for:

✔ Proven industry experience

✔ High-quality, certified machines

✔ Technical consultation & support

✔ Spare parts & after-sales service

✔ Training and commissioning assistance

✔ UAE-wide availability

Why Choose Global Fasteners as Your Laser Welding Machine Supplier

Global Fasteners goes beyond standard equipment supply.

✅ Industry Expertise

With over 13 years of industrial experience, we understand real-world production challenges.

✅ Advanced Technology

We supply modern laser welding machines designed for efficiency, durability, and precision.

✅ Complete Industrial Solutions

From fasteners and welding accessories to advanced equipment, we offer end-to-end support.

✅ UAE & GCC Coverage

Fast availability and logistics support across major industrial zones.

✅ Trusted Partner Approach

We help clients select the right machine for their production goals—not just sell equipment.

Future of Laser Welding in UAE & GCC

With increasing focus on:

- Smart manufacturing

- Sustainable production

- Faster construction timelines

Laser welding machines will continue to play a central role in industrial growth across the region.

Conclusion

Laser welding machines are transforming how industries approach fabrication, offering unmatched speed, precision, and cost efficiency. By reducing rework, enhancing weld quality, and enabling automation, laser welding significantly improves production efficiency.

As a reliable laser welding machine supplier, Global Fasteners helps businesses upgrade their manufacturing capabilities with confidence and long-term value.

📞 Contact Global Fasteners today

Upgrade your production efficiency with advanced laser welding technology.

✅ FAQs

Q1: Is laser welding suitable for heavy industrial applications?

Yes, modern laser welding machines handle both light and heavy-duty industrial applications.

Q2: Does laser welding reduce production costs?

Absolutely—faster welding speeds and less rework significantly lower operational costs.

Q3: Do you provide after-sales support for laser welding machines?

Yes, Global Fasteners offers technical support and guidance for all supplied machines.