Depending on the world’s view, it always hangs upside down, whether construction, manufacturing, oil and gas, or infrastructure, without a definitive end. The marvelous towers, giant bridges, and super machines are only visible in their construction. Behind every creation, however, there is one common thread holding it all together: fasteners.

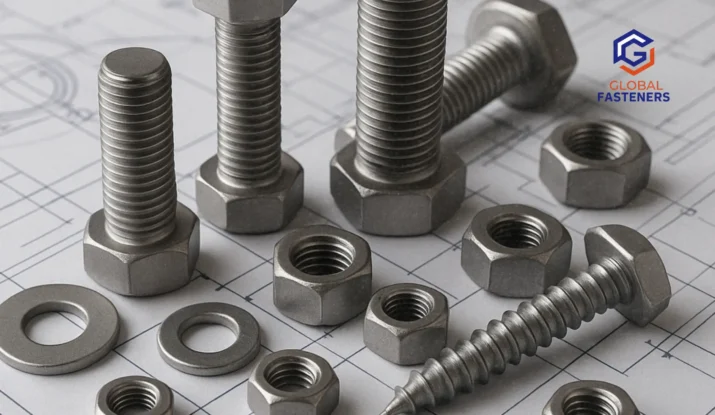

From the Burj Khalifa in Dubai to offshore rigs in the Arabian Gulf, fasteners — bolts, screws, washers, nuts, anchors, and threaded rods — are the real heroes of strength, stability, and safety for the largest, most complex projects in the world.

🔧 Importance of Fasteners Beyond Simple Metal Parts

These fasteners are not simple add-ons, they actually infinite load parameter components. Beyond that: not only “plug-together.” A right fastener increases its lifespan, enriches safety, and the associated longevity of costs.

The industries rely heavily and depend for their high-tensile fasteners, bolts that are corrosion-resistant, and marine-grade fasteners, covering performance in extremes of pressure, temperature, and exposure to environments.

Some applications related are:

-

Steel structure fasteners for bridges and towers

-

Heavy-duty bolts for oil & gas pipelines

-

Self-tapping screws for HVAC and ductwork systems

-

Stainless steel fasteners for marine, coastal, and chemical plants

-

Anchor bolts in concrete for foundation safety

🏙️ Constructing Megastructures with Precision Fasteners

High-rise construction is not exempt from this stereotype. In the Middle East, it would prove relatively future tense and complicated. Here comes the need for strength, precise weather resistance, and vibration provisions. Again, it comes back to the fastener quality.

Otherwise, improper selection comes to include components such as:

-

DIN 933 hex bolts

-

ISO 898-1 grade 10.9 bolts

-

Hot-dip galvanized nuts and washers

-

U-bolts and stud bolts

might pose a threat to structural integrity for building something so enormous.

Hence, it’s not a luxury to source from a certified industrial fastener supplier in UAE; it’s a necessity.

🧪 Materials Matter: Right Fasteners for the Right Job

It is all about the materials of fasteners. A lot of wrong ones have ended up with corrosion, failures, and down time of expensive production amounts. Here are some top materials that will be used with regard to large scale projects:

-

Stainless steel 304/316 – suited to outdoor and marine applications with high moisture

-

Carbon steel – commercially viable and often used in structural work

-

Alloy steel bolts – for high-performance applications like engines, turbines, and pipelines

-

Brass and copper – excellent electrical conductivity for panels and terminals

-

Titanium – lightweight and anti-corrosive, usable in aerospace and medicine

Look for ISO 9001-certified suppliers of fasteners to guarantee that the materials meet international testing standards.

🧰 Fasteners for Every Industry

The demand for precision-engineered fasteners seems to be ever-growing across industries. Whether the rugged requirements of oil and gas pipelines or the sleek presentation of solar installations, modern engineering requires many reliable fastening solutions.

-

Heavy-duty construction screws that can withstand high stress and vibration

-

Hot-dip galvanized bolts that provide exceptional corrosion resistance

-

High tensile grade 10.9 and 12.9 bolts for structural steel and machinery

-

Marine-grade stainless steel for offshore and shipbuilding

-

Anchor bolts and threaded rods used in concrete and equipment foundations

Choosing the right fastener could make or break a project — whether it concerns Dubai’s rapidly growing construction zones, remote oilfields, or high-rise buildings. That’s why one should source from ISO-certified fastener suppliers in the UAE to maintain performance and safety compliance.

🌍 The Global Industrial Fasteners Market is Booming

Market studies conducted recently indicate that the world’s fastener market would be within USD 124 billion by the year 2030. This shows an increase induced by infrastructure and manufacturing demands emerging on a grand scale.

GCC countries, along with the UAE and Saudi Arabia, will face new demands in areas such as:

-

B2B fastener distribution

-

Bulk fastener supply for construction companies

-

Custom fasteners for OEMs and machinery

-

Marine fasteners for shipping and ports

-

Aerospace-grade fasteners for aviation projects

🛠️ How One Chooses the Best Fastener Supplier in UAE

If you are in a construction company, engineering, or procurement, you will need a supplier not just with a catalog of products. What you need is:

✅ Wide variety: Nuts, bolts, washers, screws, threaded rods, anchor bolts

✅ Compliance: ISO, ASTM, DIN, and BS standard fasteners

✅ Expertise: Custom fastener recommendations for your specific project

✅ Fast shipping: On-time delivery for urgent construction timelines

✅ Local support: Based in UAE for faster service and consultation

This is where Global Fasteners comes in: your trusted source of precision fasteners in the UAE and GCC.

⚙️ Future of Fasteners: Smarter, Stronger, Greener

The fasteners industry is rapidly changing. Today, engineers are:

-

Using smart fasteners for torque monitoring

-

Requiring advanced coatings for long-term corrosion resistance

-

Implementing vibration-resistant locking systems

-

Demanding zinc-free and nickel-free eco-friendly options

-

Ordering laser-marked bolts for full traceability

As construction technology advances, fasteners must keep pace. Partnering with a modern fastener supplier ensures your projects are future-ready.

✅ Conclusion: Tiny Parts, Huge Contribution

The next time you are walking inside a skyscraper, boarding a ship, or riding on a metro train, remember: fasteners are very much holding it all together.

Fasteners are the silent workhorses for every successful project — from high-tensile bolts in steel frames to corrosion-resistant screws in coastal zones.

Searching for bulk fasteners, custom bolts, or marine-grade supplies?

Choose a supplier that understands quality, engineering, and urgency.